Display development is a complex task and is divided into the following concept steps:

- Definition of the products to be offered on the display (dimension, weight, number).

- Definition of the target groups – if, for example, sales to major distributors are envisaged, where there are certain specifications regarding the total height of secondary placements

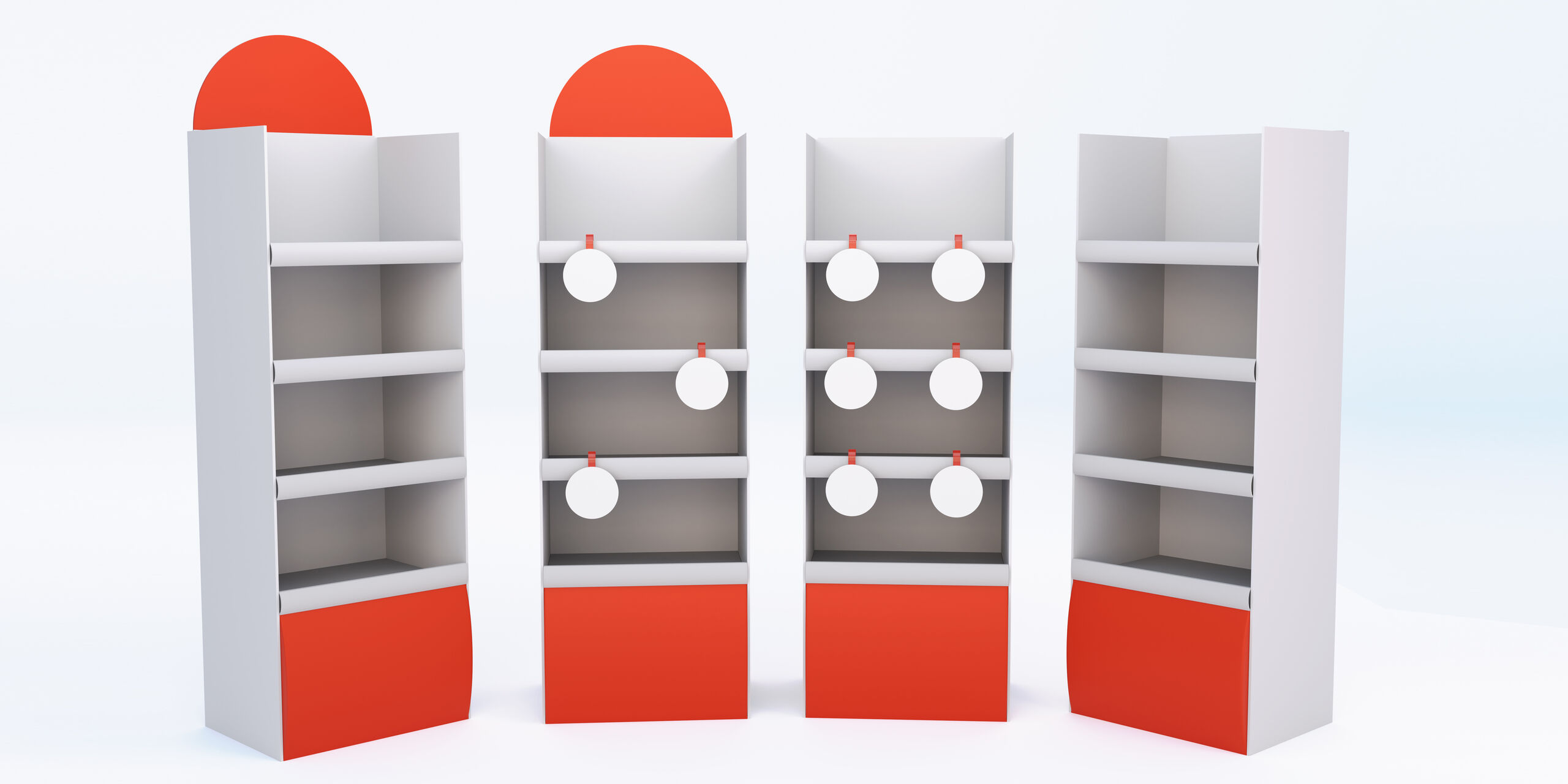

- Digital development of a prototype

- Production of a sample display that is used for a test placement

- Graphic design of the display

- Printing and production of the display

- The upper shelf is enlarged and extends beyond the base area of 60 x 40 cm - a product is shown unpacked on this shelf.

- The basic colour of the "Papa Papillon" brand can be found on the top board, the side panels and each shelf.

Load capacity

Displays are usually made of corrugated board laminated with cardboard. The number of layers of corrugated cardboard and the construction result in the stability. The following example shows a so-called "heavy-duty display". Each shelf can carry up to 25 kg - the entire display 125 kg. This is possible without "bending" of the individual trays.

Counter displays

Of course, it doesn't always have to be the so-called ¼-pallet displays. Especially for smaller packages, e.g. for seeds or plant care products, 60 x 40 cm counter displays are ideal.

In the following example, flower mixtures are offered. The different varieties are separated from each other by cardboard strips. With a matching outer box, the product can be shipped very easily.

These examples show how diverse the possibilities for displays can be. We look forward to the dialogue with you and will be happy to create a concept and an offer - tailored to your products. Get in touch with us.